New builds on the workbench are slow in coming for now. So here are some photos of a build I did back in 2006 and finished in 2007. Inspiration came from photos on line of small size airport crash trucks that could handle small plane incidents. It all started with the desire to come up with a Dodge W series cab of the mid 1960's. With some discussion with friend and fellow modeler, Jeff Harper, I took a Ford cab and turned it into a Dodge cab for 1966. It actually started back in 2004 with the Dodge W-300 that Tom Coolidge cast from the master that was made from the Ford.

Hosted on Fotki

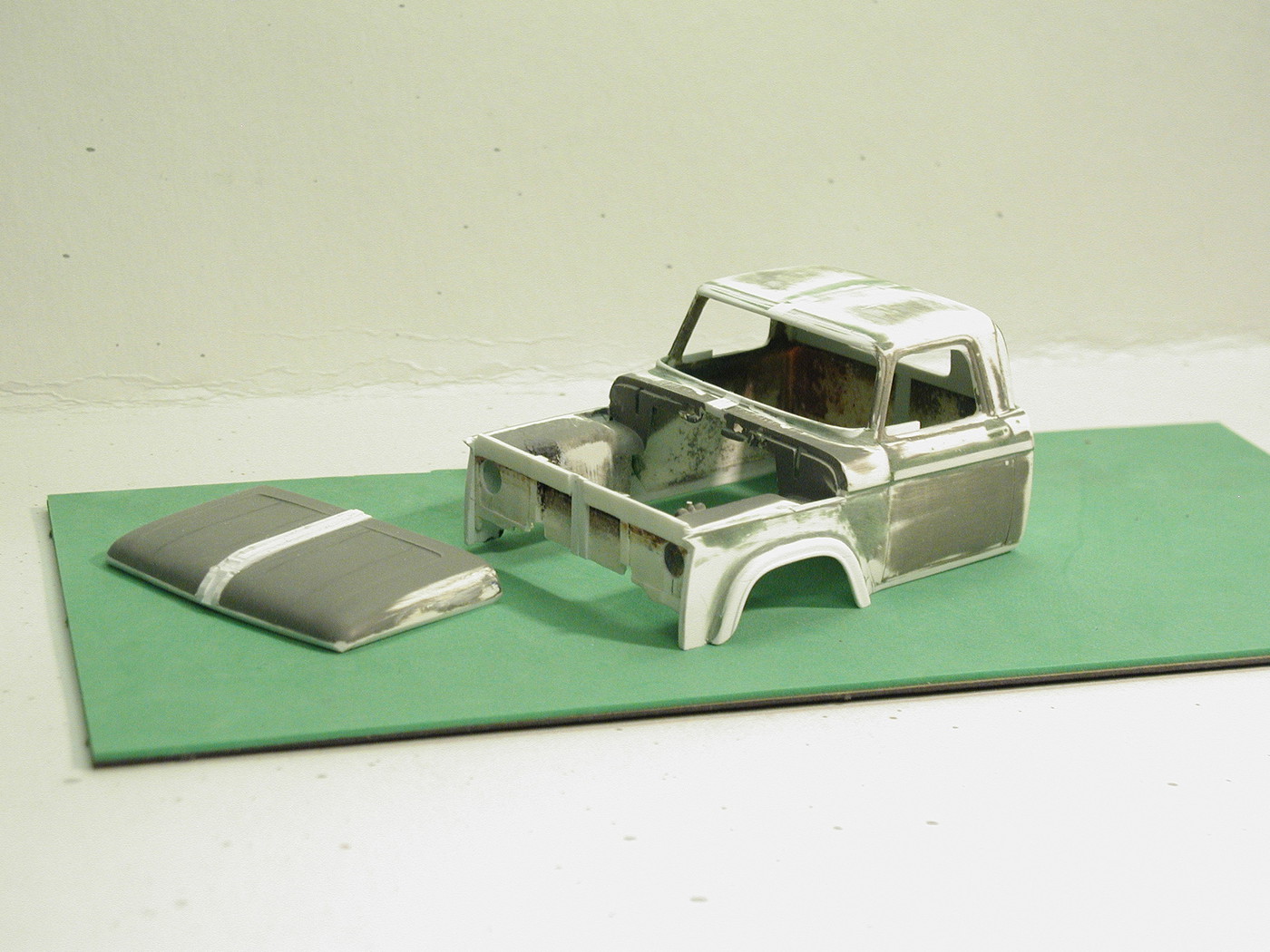

The accent line across the doors was very similar to a Dodge so I used that as a starting point. The front fenders were cut off, the cab was split down the middle to add 1/4" strip stock and the shape of the windshield and side windows was changed.

Hosted on Fotki

The back of the cab was also changed to show a full accent line across the top, a small rear window and the accent indentations on each side. Flairs were added to each fender using strip stock and Squadron (when it was good stuff) for the blend into the fenders. The drip edge above the doors were sanded clean and new door lines were cut based on line drawings from a 1970 Dodge body builder's book. In the first photo the hood was also cut and made 1/4" wider. With that done, I cut the hood down the sides were the contour lines were to drop it some. Louvers were added with strips of plastic quarter round stock.

Hosted on Fotki

A grill was made using strip brass and headlight surrounds were taken from the Dodge L-700 kit. The outside headlight trim is turned aluminum. The photo above shows the change in the windshield and door lines. The rest of the build was for a different model but this was the basis for the change to a W-500 that would be used for the crash rig.

Hosted on Fotki

Tom Coolidge cast the W-300 cab and then I modified it with a 1968 grill, wider fender flairs and a larger rear window.

Hosted on Fotki

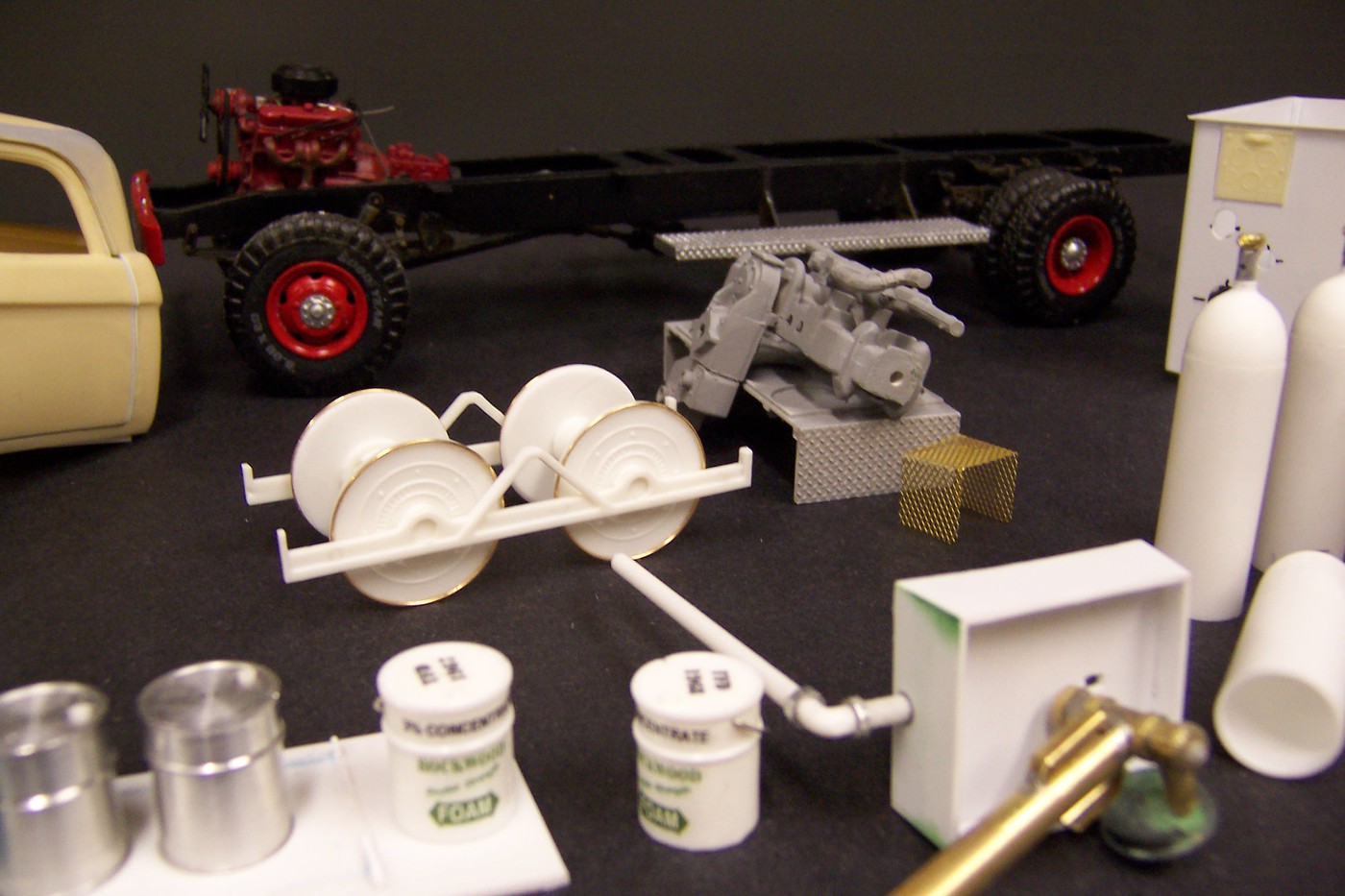

The W-500 was built from dimensions obtained from the Dodge body builder book and photos of similar rigs that I found on line. Since this was to be a build for the "Village of Tremont Municipal Airport", a number of different details were incorporated into the "specifications". Frame is Evergreen strip stock and the axles are castings of the AMT ALF kit. Tires were resin cast using a photoetch tread pattern that was wrapped around a resin tire blank. In the background is one of the line drawing sheets that came from the Dodge book. The page was copied and scaled to 1:25 for direct measurements.

Hosted on Fotki

The mockup of the cab and body is done with a temporary foam nozzle sitting on top of the cab. It was not used for the final build but gives an idea of what would be next.

Hosted on Fotki

The doors were opened and hinged. The engine is a basic Dodge kit piece that was set between the frame rails.

Hosted on Fotki

Here are some of the things that went into the build. The Hale pump is from the ALF. So are the hose reels but they were sanded down to be much thinner like a steel disc would be and a wire edge was added. 5 Gallon foam cans were turned in aluminum and then cast. The beginning of the foam turret nozzle is seen in brass.

Hosted on Fotki

After some Duplicolor #398 red was sprayed on, the details began to be added. In this photo the front running boards are not yet attached and much of the detail for the body is missing. The CO2 cascade system was made of plastic tube stock with the tops made from a turned master. Wire, craft beads and plastic carved nozzles were added.

Hosted on Fotki

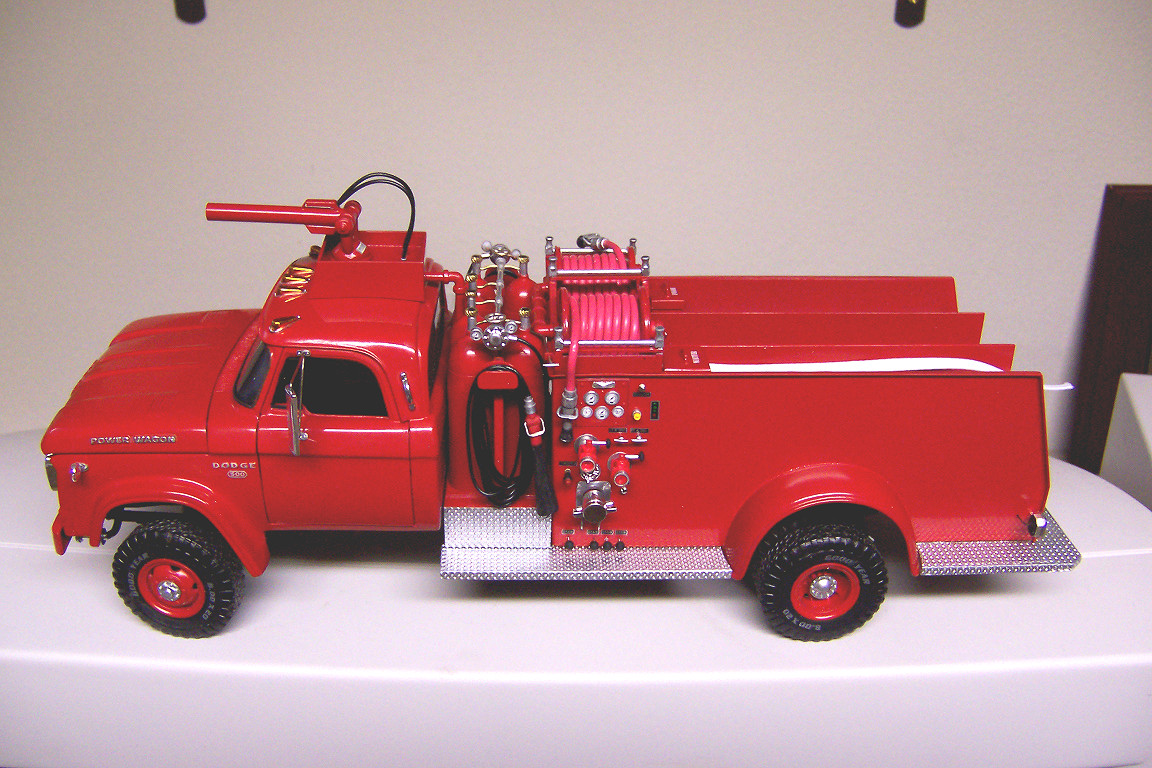

Brand new out of the factory and ready for service. The decals were computer generated and printed on the ALPS. The tools on the side of the body were done in aluminum.

Hosted on Fotki

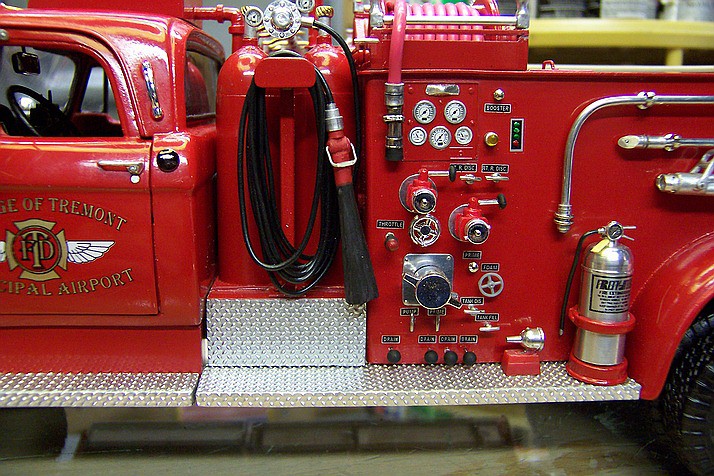

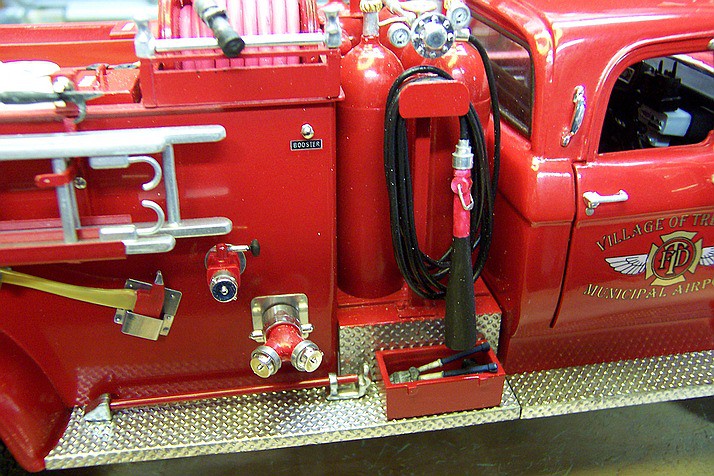

The pump panel details include Hobbytown caps for intake and discharge lines, aluminum flashing for trim, photographed gage faces, common pin discharge handles and ALPS printed labels.

Hosted on Fotki

The axe holder is aluminum flashing, polished and folded. Tools came from the parts box. The running boards were made of Hobbytown treadplate but the edges are embossed aluminum foil that were superglued on and then trimmed.

Hosted on Fotki

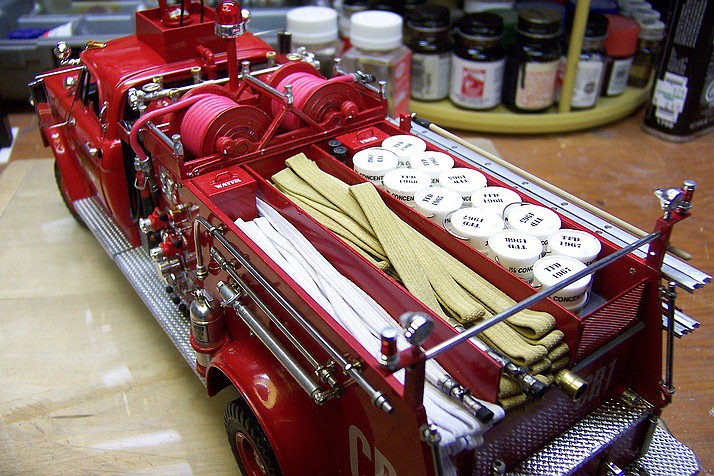

Top view of the finished truck shows the cast foam cans and hose that was made of sewing elastic. It can be stained, as was done for the 2-1/2" supply lines. Couplings are brass and aluminum tubing, nozzles are DomMillsModels white metal and the booster hose on the reels is red electrical wire.

The truck sits in the case along with its sister Dodge, W-300 that got the whole thing started.

Hosted on Fotki

Hope you enjoyed the ride.