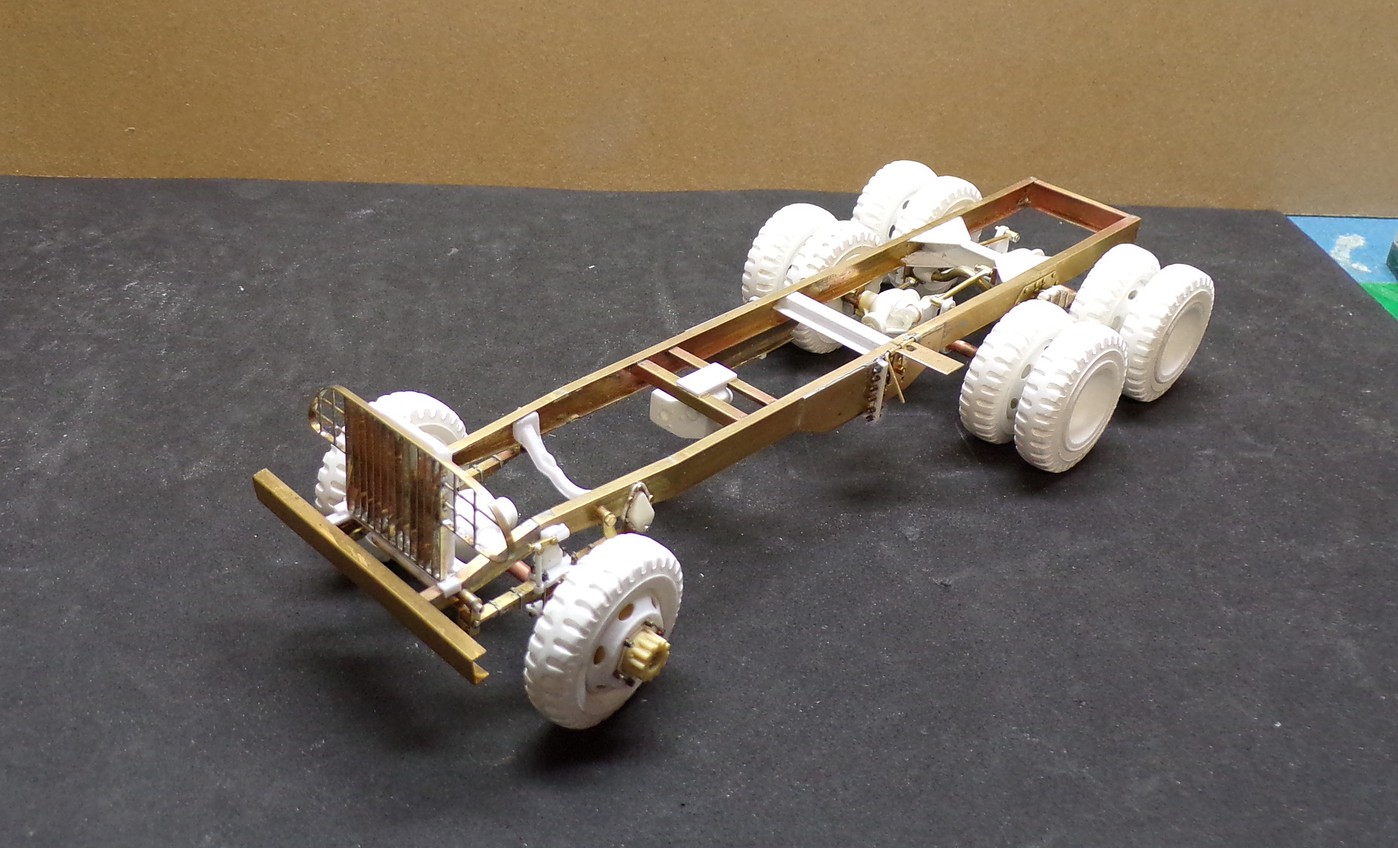

After several sessions at the work bench the frame for the CCKW is coming together.

Hosted on Fotki

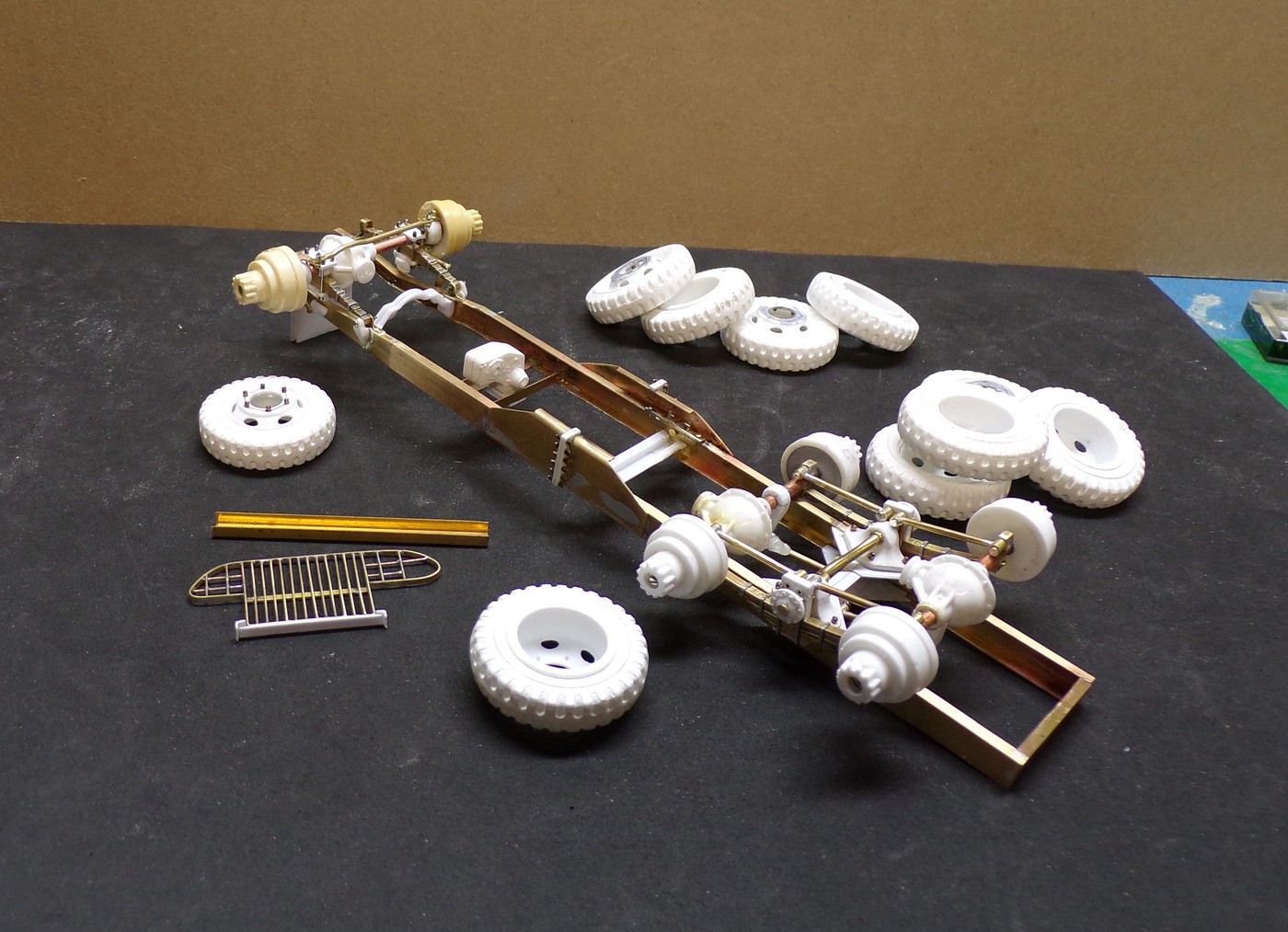

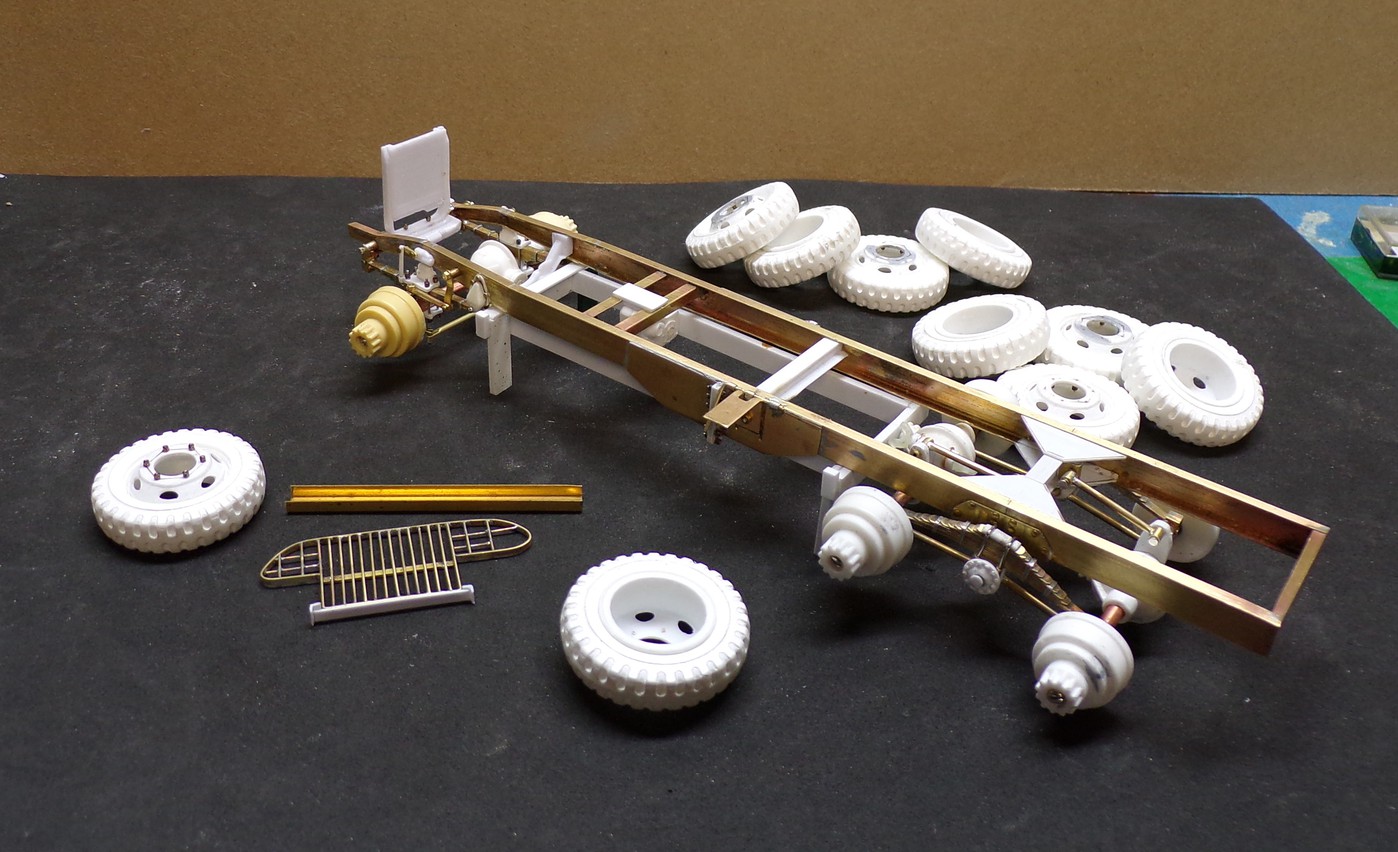

Multiple things have been going on starting with the new 6 hole wheels. I had the masters for the wheels 3D printed. I filled in the 6 holes with crystalclear so that a two part mold could be made. When the resin castings were set and removed the holes were cleaned up with a small oval file. The lug nuts are #15 fusion beads held in place with some brass craft wire. The wheels were ever so slightly loose in the resin cast wheels but that was fixed by adding some 0.010 strip stock to the outside. Wheel hubs are also resin castings, drilled out in the center to accept a brass bushing.

Hosted on Fotki

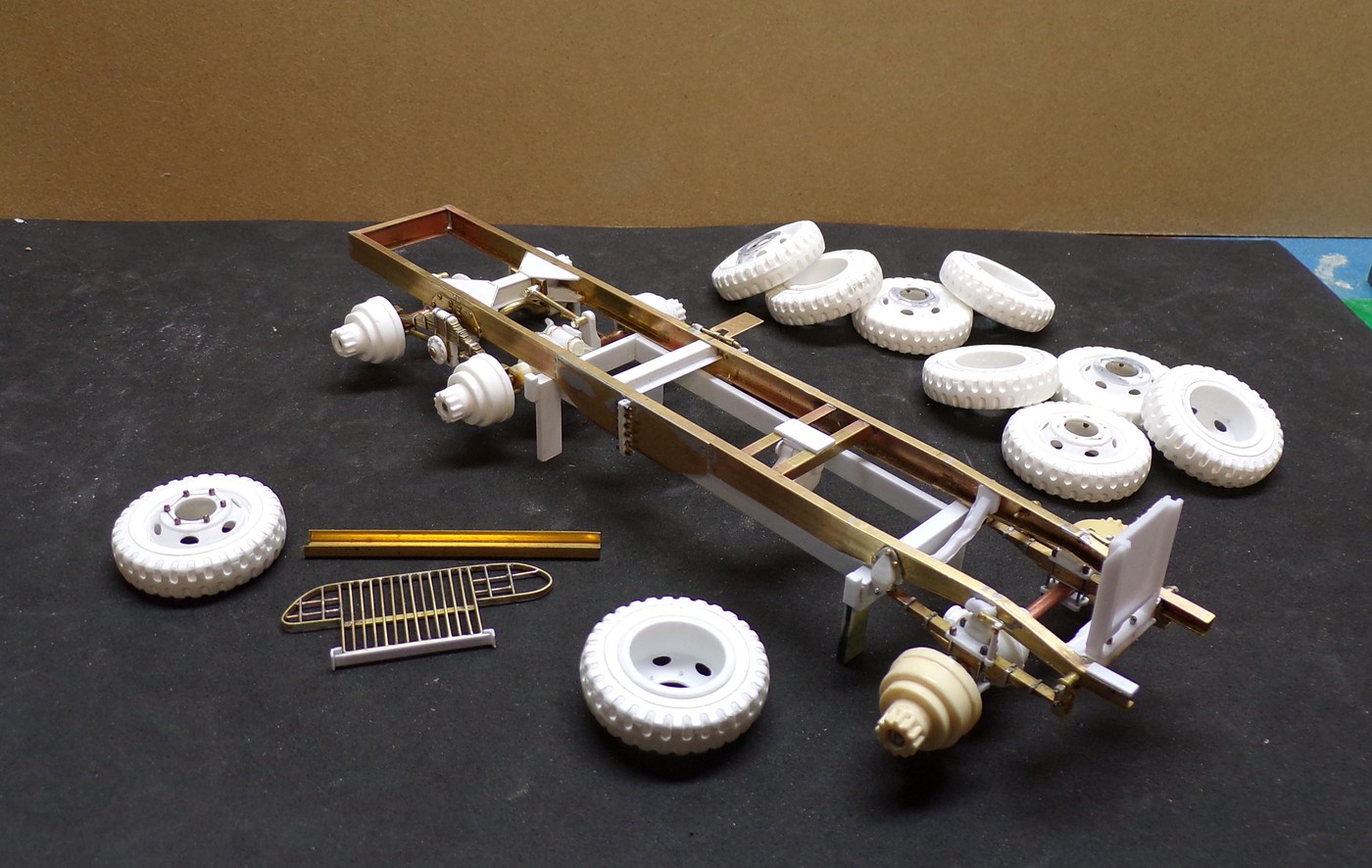

The split differentials used on this truck were also resin cast from a master taken from a Signature Series 1938 Ford. They were drilled out to accept brass axles. Springs are strips of brass stock soldered together at the ends. At the end of each main leaf a section of tubing was soldered on to attach the springs to the shackles in the front. Rear springs have no such connections and simply float on top of the two rear axles. They are held in place by torsion rods that connect the axles to the trunnion. Each spring set is "held" together with flattened solder wire. U-bolts are craft wire with fusion beads on each end. Steering linkage and tie rod have been added to the front.

Hosted on Fotki

This build has some unique features including the cluster of bolts and fishplates in the center of the frame and a spare tire bracket that folds down so that the spare can be removed. The radiator and engine supports came from the '41 Chevy pickup kit. The transfer case is a resin casting from an old kit master. The grill guard is made of 1/64 x 1/16 brass strip stock and small brass wire for the headlight protection. It is larger on one side to also protect the blackout light. The front bumper is brass channel.

Hosted on Fotki

Each axle end has a plastic rod insert held in place with CA. The centers were drilled out. The wheel hubs are held in place by small screws that go into the plastic inserts. The screw heads are just large enough to keep the hubs from slipping off the axles. Not easy to see are the beginning of the driveshaft U-joints. They are 3D printed and are connected to the pillow on top of the front split differential at the rear axles. Eventually similar U-joints will be applied to each driveshaft.